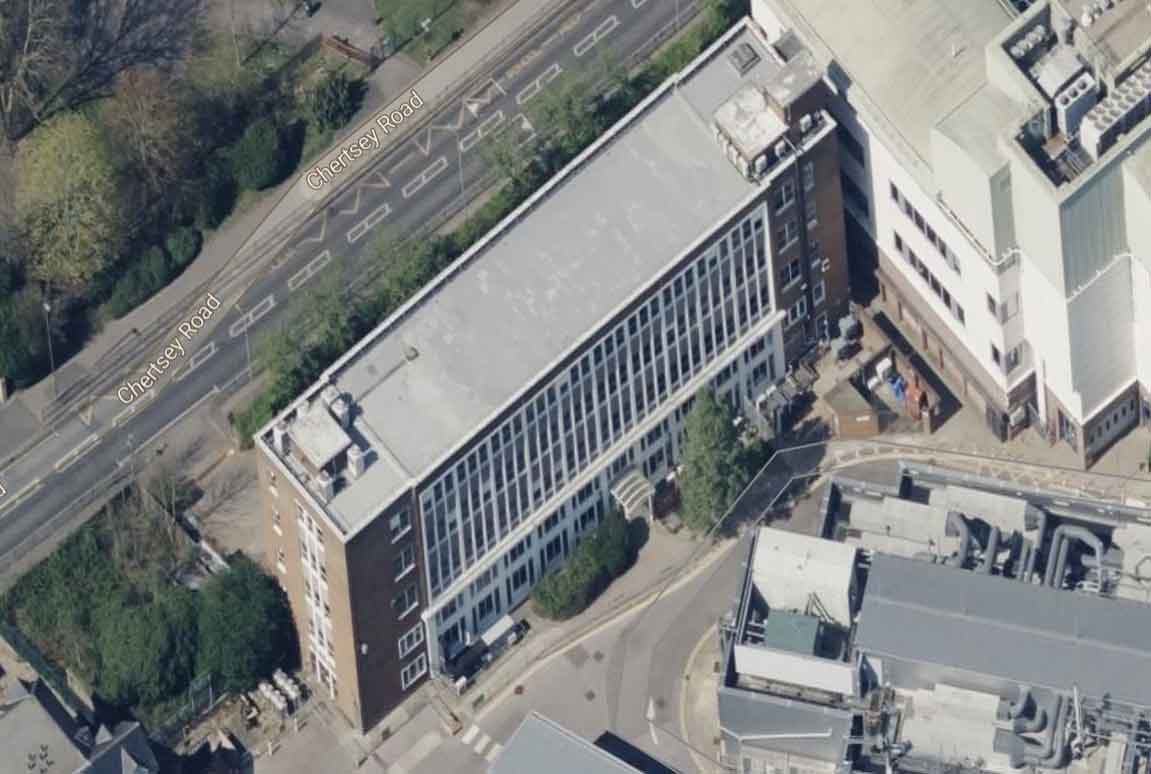

BP Building 122 - Façade Structural Inspection

- Building status: Unoccupied for an extended period at the time of inspection

- Scope: Visual structural inspection of external façades; elevation-based defect mapping; photographic schedule

- Primary risks flagged: Cracking at window perimeters/columns; bowing brickwork (Levels 4–5); biological growth and moisture ingress

- Deliverables: Defect register with priorities; annotated elevations; recommended make-safe actions; outline repair specification & monitoring plan

- Cracks in the façade

- Finding: Multiple cracks of concern, including around window openings and column locations.

- Risk: Potential loss of local integrity, water ingress, corrosion of embedded metals and heightened wind-suction vulnerability.

- Bowing bricks at Levels 4–5

- Finding: Local out-of-plane bowing noted.

- Risk: Elevated risk of leaf instability/disintegration, especially under wind loading and during freeze–thaw cycles where moisture is present.

- Biological growth (moss, algae, mould)

- Finding: Widespread organic growth consistent with persistent moisture.

- Risk: Accelerated material deterioration, blocked weeps, reduced breathability and ongoing water retention.

1) Immediate make-safe and protection

- Establish exclusion zones under affected elevations and high-risk locations (e.g., below bowing panels) pending remediation.

- Temporary debris-netting or local protection where access routes must be maintained.

- Reinforce inspection frequency after adverse weather events.

2) Crack repairs and local stability reinstatement

- Priority repair of significant cracks, especially at window heads/jambs and column interfaces.

- Techniques to include deep repointing, helical bar stitching or local rebuilding where cracking is through-leaf, with stainless-steel materials and compatible mortars.

- Check and, if required, replace/augment lintels and introduce movement joints where restraint or thermal movement is implicated.

3) Bowing brickwork management (Levels 4–5)

- Monitoring regime: Install tell-tales/targets and set trigger levels for action.

- Intrusive checks (targeted): Verify ties/anchors, cavity condition, wall build-up and any corrosion.

- Remedial options: Deconstruction and rebuild of affected panels; alternatively stainless retrofit ties and local restraint solutions where appropriate and justified by calculation.

4) Moisture management and cleaning

- Remove moss/algae/mould using methods suitable for masonry and sealants; clear weep holes and ensure cavities can drain/vent.

- Improve copings/flashings and sealant details; introduce/repair cavity trays as required to route water out of the façade.

5) Survey, QA and re-inspection

- Maintain an elevation-based defect register (P1/P2/P3 priorities) linking photographs, locations and recommended works.

- Re-inspect after repairs; update the log and move items to planned maintenance where appropriate.

- Risk reduced via immediate make-safe measures and exclusion where required.

- Clear repair roadmap: prioritised defect list, practical repair options and a monitoring plan.

- Asset knowledge improved: elevation drawings with photo references for ongoing management and future works.

Façade inspection & defect mapping · Structural risk appraisal · Immediate make-safe guidance · Repair and monitoring strategy · Contractor briefing notes · Re-inspection / QA schedule

Expertise in Complex Structural Challenges

- Advanced Engineering Solutions: Skilled in addressing intricate structural issues through innovative engineering practices.

- Innovative Approaches: Utilises cutting-edge technology and methodologies.

Customised Solutions

- Tailored Designs: Solutions crafted to meet the specific needs of each project and client.

- Client Collaboration: Works closely with clients to understand their requirements and achieve desired outcomes.

Commitment to Quality

- Stringent Quality Control: Maintains high standards throughout project execution, from design to commissioning.

- Safety Focused: Prioritises safety in all aspects of design and implementation, adhering to the highest industry standards.

GEM Enterprise specialises in comprehensive structural and civil engineering services. Our experienced team is dedicated to delivering innovative, safe, and efficient solutions for complex engineering challenges. With a commitment to excellence and client satisfaction, we provide services ranging from structural assessments to the design and implementation of bespoke engineering solutions.